Product recalls are happening more often than you think. There were 337 food recalls in 2019 (212 by the FDA and 125 by USDA FSIS), according to Food Safety magazine. Just because you don’t see recall notices on the TV or in the paper, it doesn’t mean the feds aren’t on to it.

Product recalls can happen for all kinds of reasons. Sometimes, a product might cause an injury or illness (or even death). Other times, a product might contain dangerous ingredients. Or there could just be a labeling error. Whatever the reason, you need to act quickly or you could jeopardize your business. As a product manager, you not only risk public safety if you don’t respond to recall notices, but you could face eye-watering fines. (Did you know that the FDA issues fines of up to $10,000 for non-compliance?)

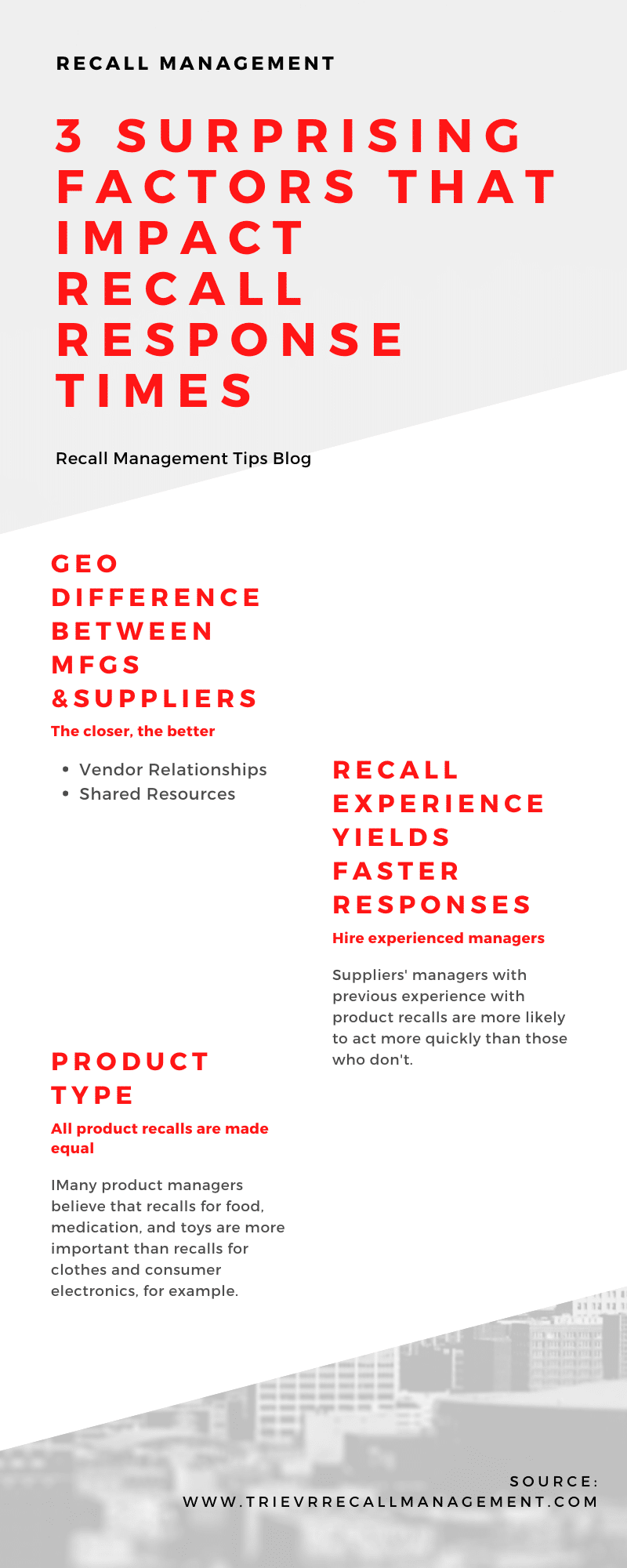

Your recall response rate — the time it takes you to respond to a recall request — is also important. But what affects response rates? This guide lists some of the reasons.

Geographic Distance Between the Supplier and Manufacturer

There’s a direct correlation between location and the length of time it takes suppliers to recall products. That’s according to a recent study by Dr. Benn Lawson at the University of Cambridge’s Judge Business School, who investigated the effect of geographic clusters on the responsiveness of food producers acknowledging product recalls.

Lawson discovered:

- Product recall response times increased when the distance between the supplier and manufacturer increased.

- Product recall response times decreased when the distance between the supplier and manufacturer decreased.

But why?

There could be various reasons. Lawson speculates that manufacturers might have closer relationships with suppliers in their local area. Suppliers in proximity to manufacturers might receive (and respond to) recall notices sooner than those further away.

Another reason is that suppliers and manufacturers in the same area often share resources, such as storage and transport. Again, suppliers in proximity to manufacturers might receive information about recalls sooner.

“Firm response time is lengthened by the geographic distance between the supplier and manufacturer, but shortened when the supplier and affected company operates in related, rather than diverse, industry sectors,” says Judge Business School.

Lawson argues that governments should increase awareness about product recalls so all suppliers receive timely information. However, due to the costs involved, it’s unlikely this will happen any time soon.

What’s the alternative?

Suppliers (and other people in the supply chain like product managers) should keep track of product recalls in real-time — and not wait for other suppliers or government agencies to notify them. This is where a good SaaS-based recall management software platform like Trievr comes in. As a product manager, you no longer have to manually handle product recalls. As a result, you can protect public safety and avoid fines. Learn more here.

Experience With Product Recalls

Lawson also discovered that suppliers with previous experience of product recalls were more likely to act quickly than those who didn’t. It seems suppliers (and product managers) who have been in business for some time know the importance of responding to recall notices promptly because of the risks involved — bad media reputation, loss of customers, public health concerns, government fines, you name it.

Product Type

Product type often influences recall response rates across all sectors. Many product managers believe that recalls for food, medication, and toys are more important than recalls for clothes and consumer electronics, for example. But take a look at the biggest recalls of all time. As you can see, recalls impact every industry, every product, and every product manager.

In reality, no one product recall is more “important” than another. The government (or an industry-specific agency) issues a recall because there’s a risk to someone or something, somewhere. The danger could be big or small, the risk could be likely or unlikely, but a product recall is always important.

As a responsible product manager, you need to respond to all recalls in a speedy timeframe. (A reliable recall management tool helps you do this.)

Final Word

Geographic distance, previous experience, and product type are just some of the factors that influence recall response rates. The truth is, though, many product managers just don’t respond quickly enough. A recall notice for a simple labeling error might not sound serious, but there could be long-term consequences for your business if you don’t respond.

Managing product recalls is tough, and it seems like there are more and more recalls these days. Investing in a recall management platform like Trievr provides you with peace of mind. You can automate recalls, create recall templates, set up auto-reminders, access real-time reports, and much more on one system. There’s no need for multiple pieces of software. Click here for a live demo!